Finite Element Analysis (FEA)

Have Confidence in Your Design.

At KAYO Engineering Inc., we specialize in providing FE analysis for unique and complex design that cannot be accurately assessed using traditional calculations or standard code-based methods. This is most often due to complicated / unique design variables such as geometry, loading, or constraints.

Our FE analysis allows us to assess how a component responds to applied design loads—typically in terms of stress and deflection. This enables us to determine whether a design is structurally sound and capable of meeting performance requirements under specified conditions.

Our FEA Background

At KAYO Engineering Inc., we bring years of experience in applying Finite Element Analysis (FEA) to a wide range of engineering challenges. Our expertise includes both linear and nonlinear analysis, static simulations, and buckling assessments.

Whether supporting new product development, failure investigations, or design optimization, our FEA background ensures we deliver accurate, reliable, and actionable insights to inform critical engineering decisions.

-

To give our customers confidence in design analysis by:

Identifying applicable codes and regulations for the application, and ensuring the design meets or exceeds all requirements

Providing high quality FEA services efficiently to keep customer costs low

Relying on our design and manufacturing experience to provide practical and efficient design iteration recommendations

-

Experience and Training in FEA Application

Our FEA personnel have been trained and have the necessary experience to provide analysis you can be confident in.

“Straight Shooter” Mentality

When we receive requests for analysis, we will consider the best (and lowest cost) solution for the analysis. If traditional methods are better suited for your application, we’ll let you know and gladly support that approach. While we enjoy performing FEA, we enjoy satisfied clients even more!

Expert Code and Regulatory Experience

We have extensive experience performing analyses that comply with relevant codes and regulatory requirements. Our deliverables (reports, letters, etc.) are tailored to meet the applicable requirements.

CRN Registration Support Across Canada

We specialize in CRN (Canadian Registration Number) applications and work directly with pressure authorities like ABSA, TSSA, TSBC, and others—managing the process from submission to approval.

Learn more about our CRN Services.

Our FEA Services

Pressure Equipment Analysis

In Canada, all pressure equipment which must be registered in accordance with CSA B51 will also require the analysis to meet the requirements of CSA B51 Appendix J, as well as any provincial Boiler Authority requirements (eg. ABSA document AB-520 in Alberta). KAYO Engineering Inc. performs analysis and provides documentation which meet these strict requirements.

For pressure equipment KAYO Engineering Inc. uses FEA software to perform analysis in accordance with ASME BPVC Section VIII Div. 2 Part 5: Design by Analysis. This code provides rules and criteria for protection against many typical failure modes experienced by pressure equipment. These include:

-

Plastic Collapse refers to failure in a component due to insufficient strength / wall thickness when subjected to primary stresses, leading to complete failure or gross distortion under applied loading, exclusive of secondary and peak stresses.

-

Local failure refers to failure in a component due to insufficient strength / wall thickness to withstand the combination of local stresses in a component subjected to internal pressure and vessel dead loads.

-

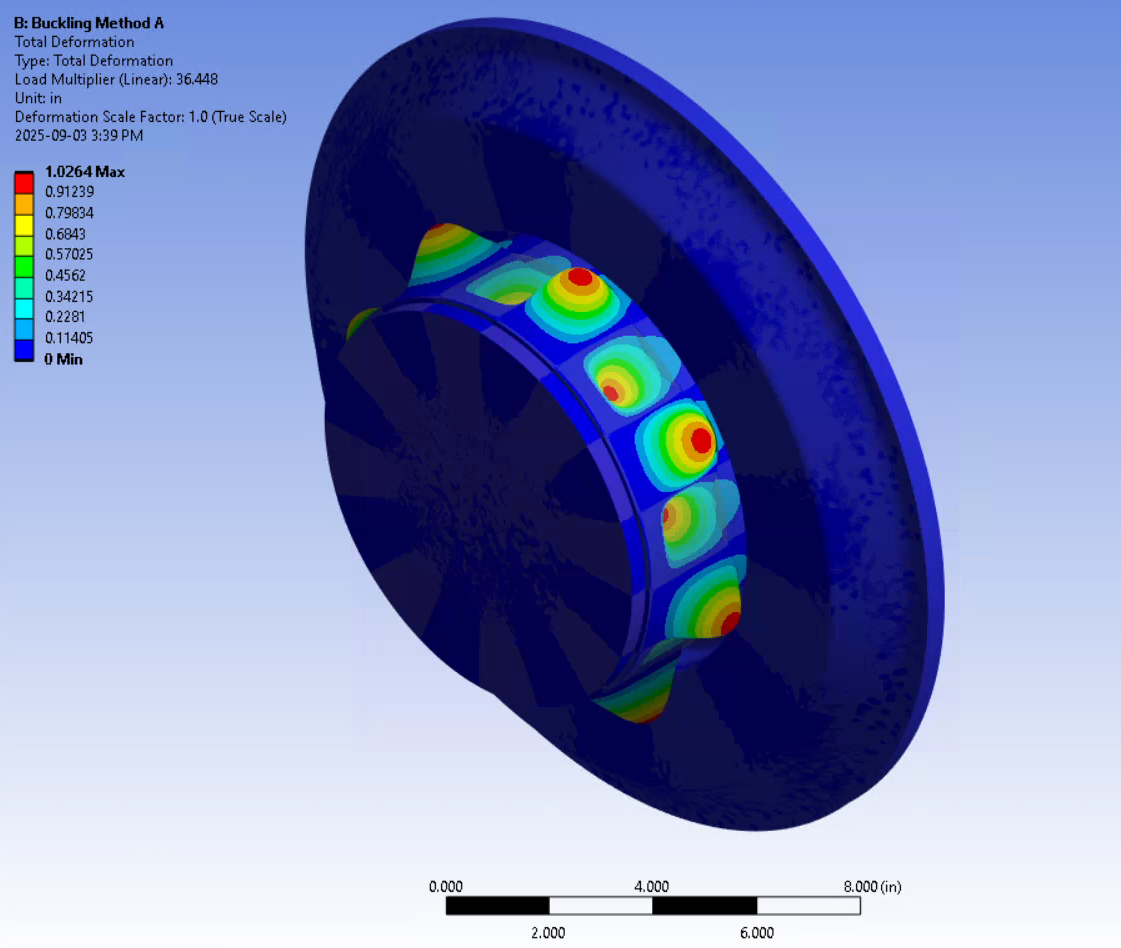

Buckling refers to failure in a component due insufficient strength / wall thickness to withstand compressive loads/stresses, leading to inelastic buckling (collapse).

-

Failure from cyclic loading refers failure in a component due to insufficient strength / wall thickness when a component is subjected to a cyclic tensile stress range. This can be further broken down into two categories which require consideration:

Fatigue: This failure mode is primarily driven by stress concentrations (primary + secondary + peak stresses) resulting in accumulated material damage over time.

Ratcheting: This failure mode is primarily driven by cyclic secondary stresses (primary + secondary stresses) resulting in progressive distortion that could reduce the collapse strength, buckling strength and / or serviceability of the component.

-

Failure from Creep Damage refers to failure in a component due to insufficient strength / wall thickness when a component is subjected to stresses at a temperature at which the material’s response to static loading / stress is time dependent (i.e. sustained loading does not produce a static result).

Note that KAYO Engineering Inc. uses both linear and non-linear methods to satisfy the code requirements above, choosing whichever method seems most suitable for the application.

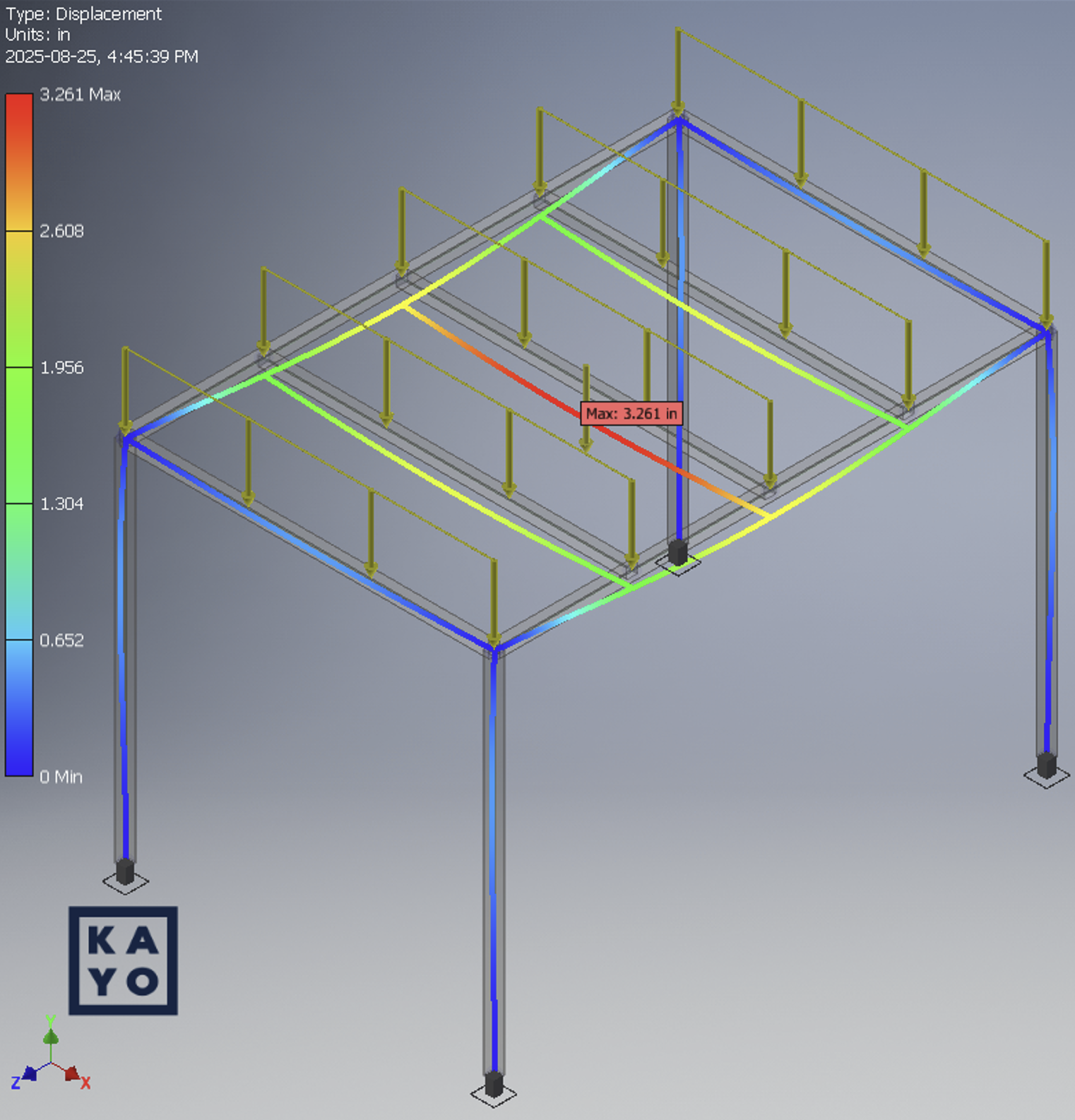

Structural Analysis

KAYO Engineering Inc. uses FEA software to simplify structural designs into a stick-frame models allowing for efficient evaluation of stresses and deflections. These results are then considered against application specific acceptance criteria to determine whether the design is acceptable and/or meets code requirements. Common codes which may be applicable include CSA S16 Design and Construction of Steel Structures, and ASME BTH-1 Design of Below-the-Hook Lifting Devices.

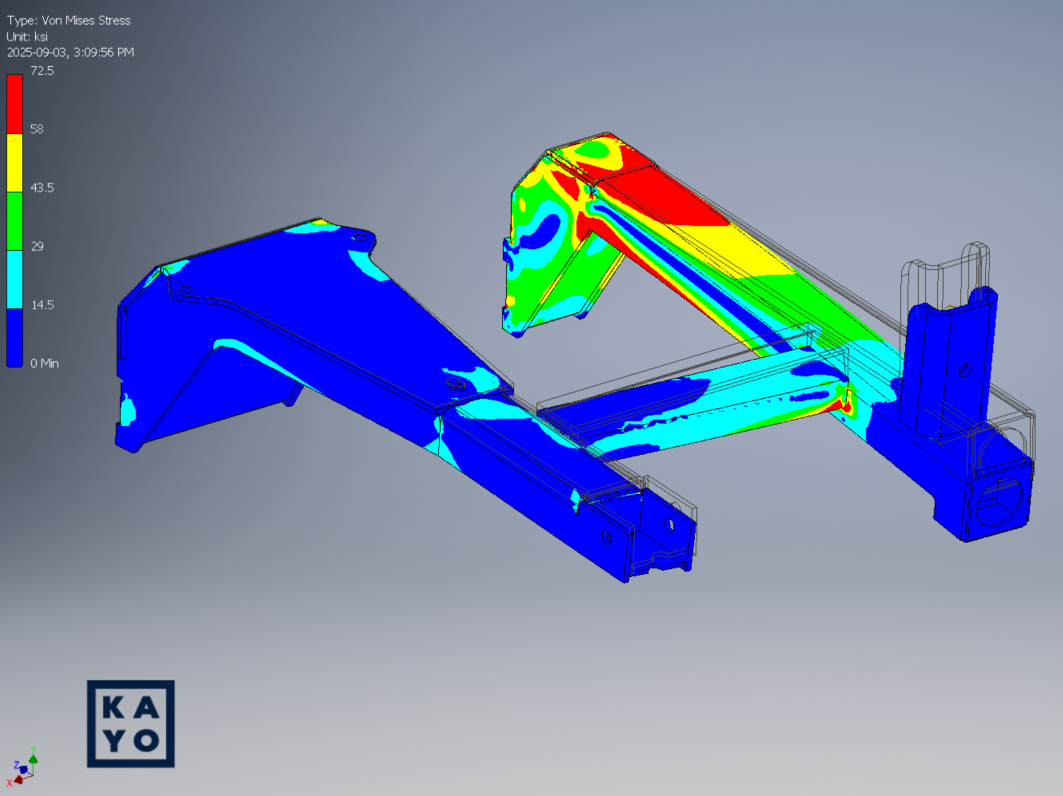

General Stress Analysis

KAYO Engineering Inc. leverages Finite Element Analysis (FEA) software to evaluate loading responses across a wide range of products and designs. This method is particularly valuable when traditional stress analysis techniques are insufficient due to complex geometries, unconventional loading conditions, or unique constraints.

Our FEA services can be used to deliver a simple pass / fail assessment under defined conditions or to establish a maximum allowable load rating for your component in its current design.

If you have a product or design that may benefit from this type of analysis, we’d be happy to discuss whether FEA is a good fit for your needs—feel free to reach out!

Finite Element Analysis FAQs

-

FEA is the act of using a Finite Element Method to determine a components reaction to imposed loading.

A more practical definition: We use advanced software as a tool to determine stresses and deflections in a component when it is subjected to a specified loading.

-

This question should always be answered prior to using FEA. The answer is often dependent on many factors including code requirements, applicability of traditional analysis methods, and criticality of application.

In many cases, with a little creative thinking, existing theoretical methods may (and often should!) be used by considering a simplified, conservative approach to the problem. However, when optimization or material constraints are priority, FEA can help ensure these design constraints are met.

We are here to support you whenever FEA is needed and would be happy to help determine if it’s the right solution for your application.

-

There’s no single global standard, but KAYO considers the following when performing FEA:

Code and local regulatory requirements as applicable (ASME BPVC, CSA B51, ABSA, etc.)

Good-practice checks which should be applied whenever FEA is ran (mesh dependency tests, reaction force checks, comparisons to theory)

Our FE analyses are performed by experienced and trained operators. While software/hardware advances are making FEA easily available to designers (which is great!), it invites errors due to inexperience / misunderstanding of the tools available (not so great)

Secondary internal review is always performed prior to finalizing any analysis results

-

When applied appropriately, FEA is cost-effective for two reasons:

Time / cost to achieve results is reduced when compared to setting up complicated and time-consuming calculation sheets to handle unique problems

Material / fabrication cost reductions down the line may be achieved by optimizing design geometry, when compared to the results using simplified / conservative traditional analysis types

Got a Design Problem? Let’s Solve It Together.

Get expert insights from our engineers. Contact us today.