Leak Sealing

Avoid Costly Shutdowns with Engineered Leak Sealing Solutions

At KAYO Engineering Inc., we specialize in the design and engineering of Engineered Pressure Enclosures (EPEs) — safe, compliant, and effective leak sealing solutions that keep your pressurized systems online. Protect your uptime, safety, and system integrity with our custom-engineered products.

Our Leak Sealing Background

KAYO Engineering Inc. is a dedicated mechanical engineering firm with deep expertise in leak sealing. Our team of professional engineers and designers craft tailored solutions to eliminate leaks without requiring operational shutdowns.

We collaborate closely with industrial maintenance providers, operators, and plant managers to design leak sealing solution precisely tailored to your equipment, operating conditions, and regulatory requirements.

Whether you’re facing leaking gaskets, thinning pipe walls, or compromised joints, we deliver fit-for-purpose solutions engineered to meet code and perform reliably under demanding, real-world conditions.

-

To efficiently engineer innovative, fit-for-purpose leak sealing solutions that:

Prevent unscheduled shutdowns

Protect personnel and equipment

Maintain plant efficiency

Support environmental safety

-

• No Shutdown Required

Avoid costly downtime—our leak sealing solutions are engineered to be installed while systems remain pressurized and operational.

• Engineered Solutions, Stamped and Certified

Each EPE is reviewed and approved by a licensed professional engineer, accompanied by a complete P.Eng.-stamped design package to ensure safety, performance, and compliance with all applicable regulations.

• Expert Knowledge of Pressure Equipment Codes

With years of experience, we design in full compliance with industry standards, including CSA B51, ASME BPVC Section VIII Div. 1, ASME B31.1, ASME B31.3, and ASME PCC-2.

• CRN Registration Support Across Canada

We specialize in CRN (Canadian Registration Number) applications and work directly with pressure authorities like ABSA, TSSA, TSBC, and others—managing the process from submission to approval.

• Safety First

Our designs prioritize mechanical integrity and operator safety, minimizing risks during and after installation.

• Responsive and Reliable Service

We deliver prompt turnaround for urgent repairs or planned maintenance, minimizing risks and maximizing uptime.

• Trusted by Critical Industries

Serving oil & gas, power generation, nuclear, petrochemical, manufacturing, and other sectors where failure isn’t an option.

Our Leak Sealing Process

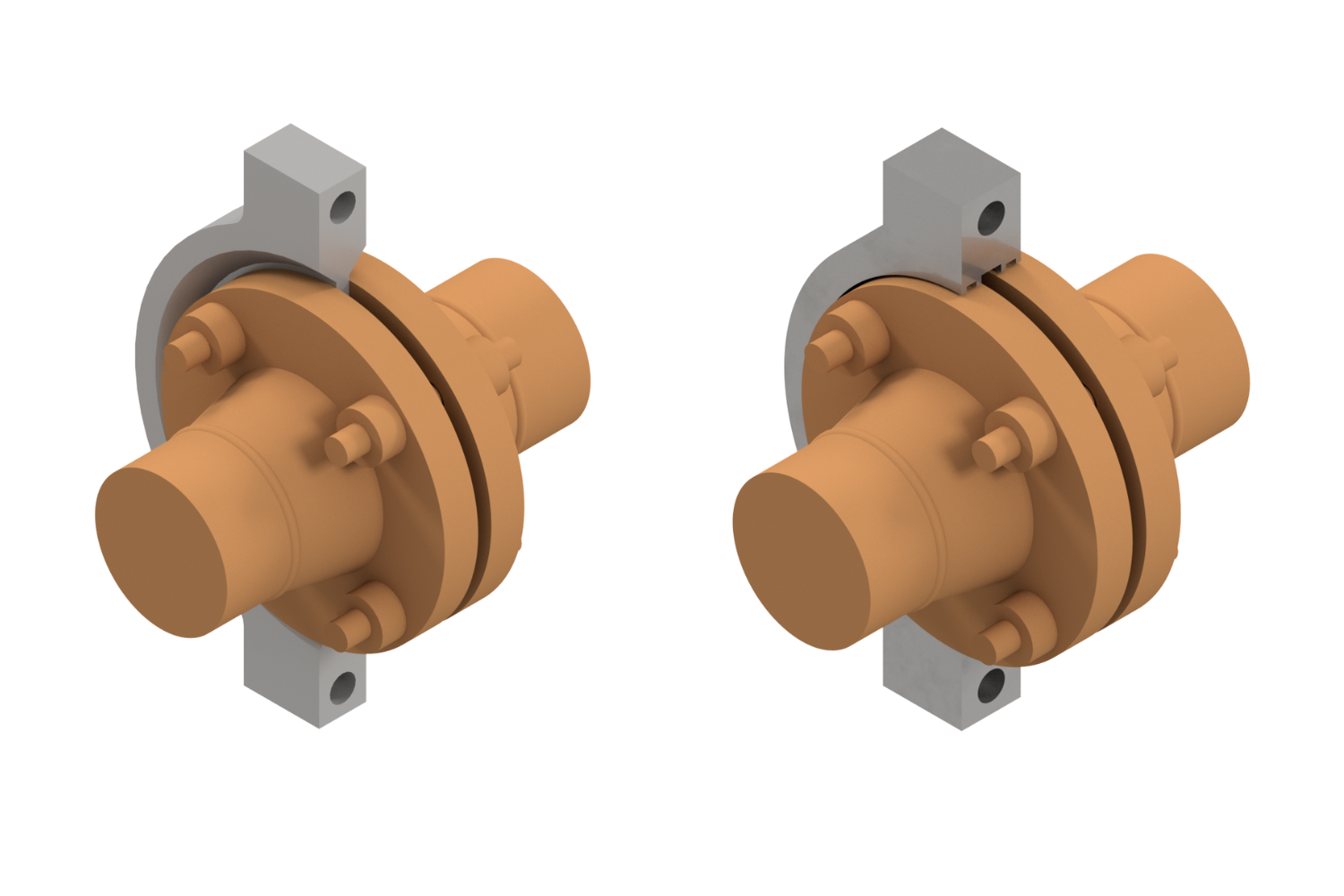

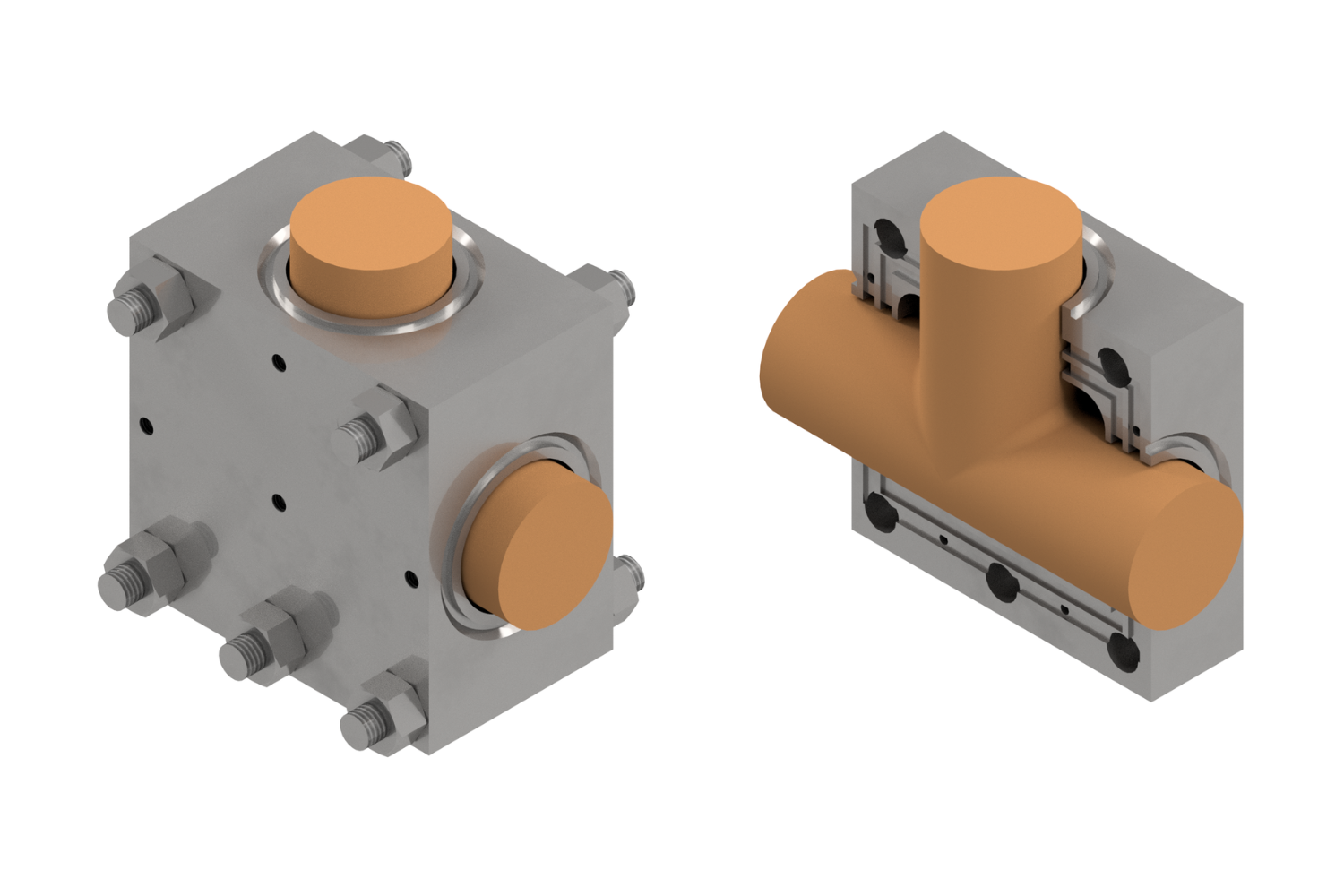

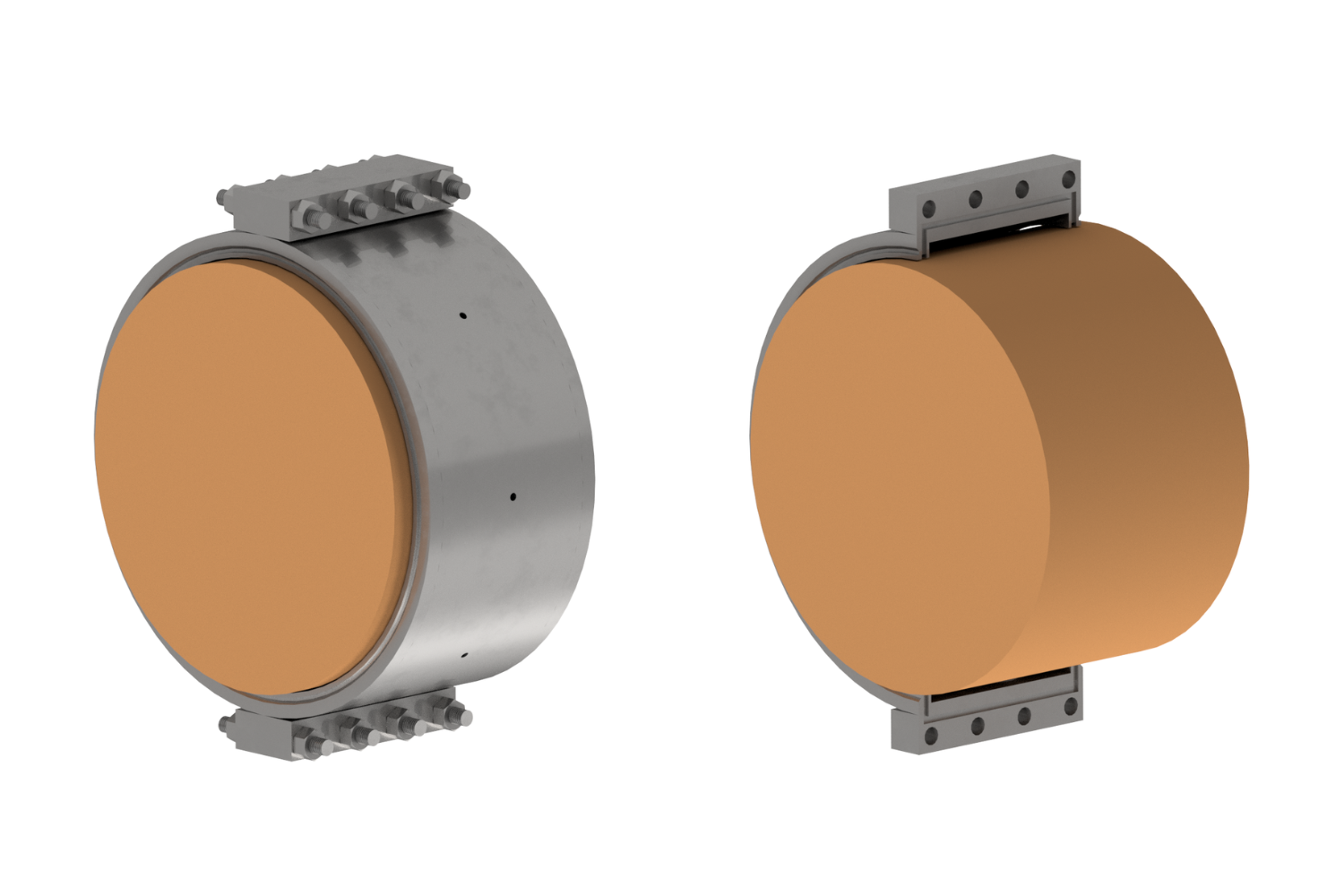

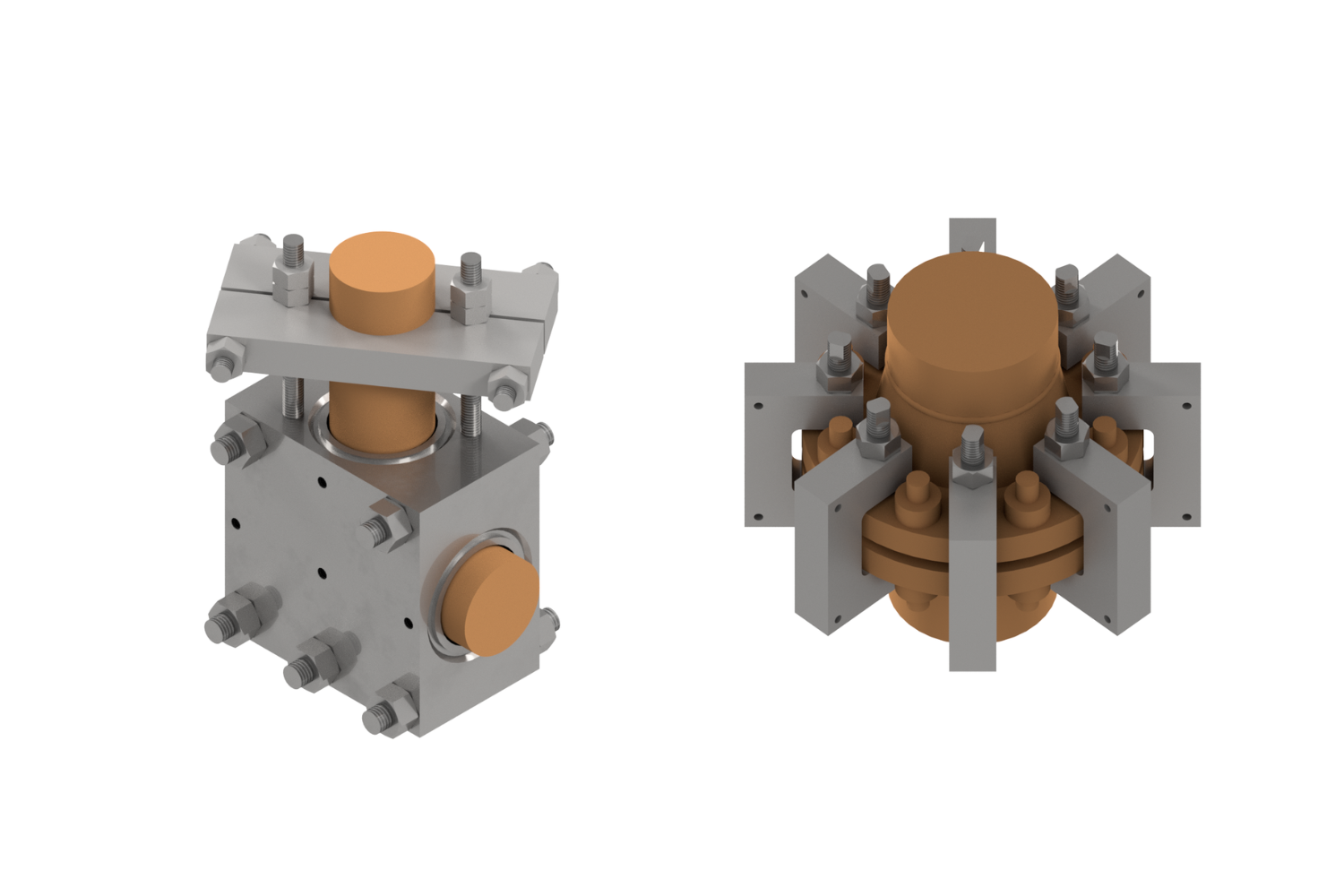

Common Leak Sealing Solutions

Industries Served

Our leak sealing solutions support safety and uptime in:

Oil & Gas

Petrochemical & Refining

Nuclear & Power Generation

Chemical Manufacturing

Pulp & Paper

Leak Sealing FAQs

-

It’s a process that seals leaks in pressurized systems without stopping operation—no shutdown required.

-

Leaking gaskets or gasket failures

Leaking flanges

Elbow leaks

Leaking valves

Threaded joint leaks

Thinning or corroded pipes

Weld porosity or pinhole leaks

-

There’s no single global standard, but work is usually carried out under:

API standards

ASME codes

Local/regional pressure vessel regulations

Internal company standards

All our designs follow applicable codes (ASME, CSA B51, etc.) and are stamped by a licensed professional engineer.

-

Yes. Avoiding shutdowns can save millions in production losses, especially in continuous process industries.

-

Often it is temporary or semi-permanent, buying time until a planned shutdown. However, some EPEs can last for years.

-

You can reach us easily, and once all the necessary information is collected, designs are typically completed within 1 to 4 business days, depending on the complexity. We understand the urgency our clients face and are committed to providing accurate and reliable design timelines to support effective planning.

Request a Leak Repair Solution

Have a leak that can't wait? We're ready to help.

Speak to an Engineer Today!